FLOOR SOUNDPROOFING PRODUCTS

Ecoroll – Eco-Friendly Sound Insulation membrane for Impact Noise

Soundproofing: Impact Noise

Category: Floor / Slab

Density: 750 kg / m3

ΔL: 22.5-28 db

Ecoroll is a high-performance, eco-sustainable acoustic insulation roll designed to reduce impact and footfall noise in all types of buildings.

Made from agglomerated vulcanized rubber micro-granules (density: 750 kg/m³), Ecoroll combines exceptional soundproofing and thermal insulation properties with remarkable elasticity and durability.

Its recycled composition makes it 100% recyclable, offering an environmentally responsible solution for sound insulation without compromising performance.

Key Features and Application

Ecoroll Key Features

Thermal Insulation – Enhances energy efficiency by reducing heat transfer.

Durable & Elastic – Outstanding resistance to tearing, compression, and abrasion.

Eco-Friendly – Manufactured from recycled materials and fully recyclable.

Vibration Damping – High elasticity ensures superior vibration absorption.

Applications

Apartments and multi-storey housing

Renovation and new-build floor systems

Projects requiring improved comfort against footstep noise

- Homes and apartments

- Offices and retail spaces

- Hospitals and educational facilities

- Hotels and commercial centers

It can be used beneath screeds.

Performance & Technical Data

| Thickness (mm) | Impact Sound Insulation ΔL (dB) | Dynamic Stiffness s’ (MN/m³) | Resonance Frequency f₀ (Hz) | Thermal Resistance R (m²K/W) |

|---|---|---|---|---|

| 3 mm | 22.5 dB (certified) | 83 | 105 | 0.025 |

| 4 mm | 23.5 dB (theoretical) | 66 | 91 | 0.025 |

| 5 mm | 24.5 dB (certified) | 55 | 82 | 0.042 |

| 6 mm | 26 dB (theoretical) | 44 | 75 | 0.049 |

| 8 mm | 28 dB (theoretical) | 40 | 71 | 0.065 |

On-Site Acoustic Test Results (UNI EN ISO 140-7)

-

3 + 3 mm under 50 mm screed, brick slab + wooden floor → L’n,w = 52 dB

-

3 mm on brick slab → L’n,w = 62 dB

-

5 mm on brick ceiling + radiant floor + parquet → L’n,w = 46 dB

-

5 mm on brick ceiling + radiant floor + ceramic tiles → L’n,w = 47 dB

Recommended Use

Ecoroll is particularly suitable for:

-

Acoustic insulation of horizontal floor slabs

-

High-performance soundproofing in multi-storey buildings

-

Noise reduction in renovations and new constructions

Installation Guide

-

Install directly on the rough concrete slab.

-

Extend the material slightly up the perimeter walls to avoid sound bridges (use AKUSTIK® BORDER perimeter band for efficiency).

-

For best results, apply a polyethylene layer under the slab before installation.

-

Suitable for both single and double screed systems, and compatible with radiant (underfloor heating) setups.

Summary

Ecoroll provides an efficient, durable, and sustainable solution for impact noise reduction. Whether installed beneath floating screeds or wooden floors, it ensures superior acoustic comfort while contributing to eco-friendly construction standards.

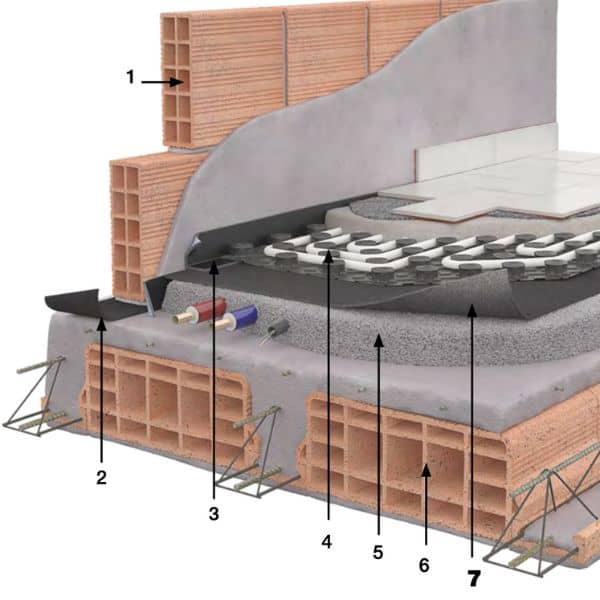

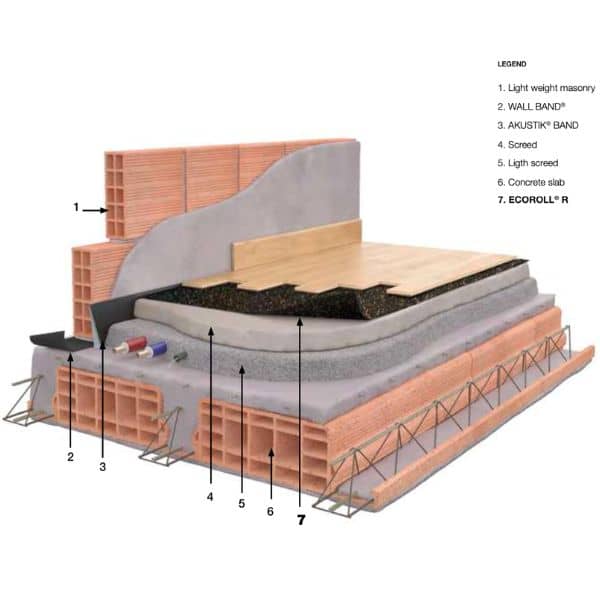

ECOROLL-R Eco-Friendly Sound Insulation membrane for Footfall Noise

Soundproofing: Impact Noise / Footfall

Category: Floor / Slab

Density: 750 kg / m3

deltaL: 15-21 db

ECOROLL® R is designed for impact sound reduction in horizontal building elements, offering reliable acoustic performance in traditional construction systems.

Made from agglomerated vulcanized rubber micro-granules (density: 750 kg/m³), Ecoroll combines exceptional soundproofing and thermal insulation properties with remarkable elasticity and durability.

This solution improves footfall noise insulation by introducing a resilient layer beneath the screed, effectively reducing the transmission of impact vibrations through the structure.

Key Features and Application

Acoustic Performance

15 dB – Ceramic tile finish

17 dB – Glued parquet flooring (15 mm)

21 dB – Floating parquet flooring

Values measured under laboratory and on-site test conditions.

Recommended Use

Apartments and multi-storey housing

Renovation and new-build floor systems

Projects requiring improved comfort against footstep noise

- Homes and apartments

- Offices and retail spaces

- Hospitals and educational facilities

- Hotels and commercial centers

It can be used beneath screeds or directly under wooden, ceramic, or floating floors.

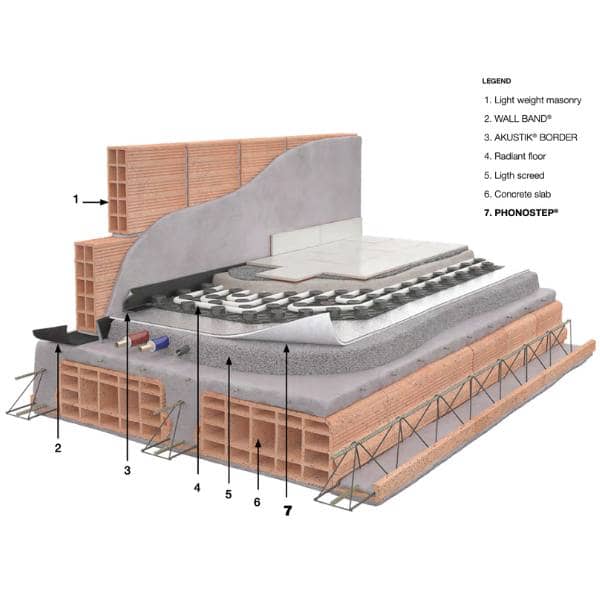

PHONOSTEP® – High-Performance Impact Sound Insulation Roll

Soundproofing: Impact Noise

Category: Floor / Slab

Density (Surface mass): 2200 g/m²

ΔL: 28-34 db

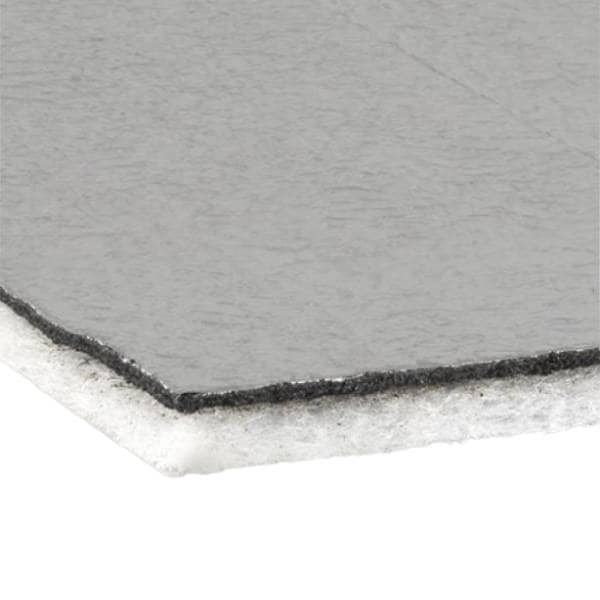

PHONOSTEP® is a bi-layer roll system specifically engineered for impact (footfall) noise insulation in floor constructions.

It combines a polymer protective layer with aluminized reflective fabric and a polyester fiber resilient mat, delivering excellent acoustic and thermal performance in modern building systems.

The product is robust, moisture-resistant, and vapor-tight, making it suitable for demanding construction environments.

Key Features and Application

PHONOSTEP Key Features

Bi-Layer Structure – Acoustic resilience combined with surface protection

Highly Durable – Resistant to tearing, foot traffic, and mechanical stress

Waterproof & Vapor Barrier – Protects floor assemblies from moisture

Thermal Contribution – Improves floor thermal insulation

Ideal for Radiant Floors – Compatible with underfloor heating systems

PHONOSTEP Applications

Residential buildings and apartments

New builds and renovations

Single or double screed systems

Lightweight and self-leveling screeds

Radiant (underfloor heating) floors

Technical Specifications – PHONOSTEP®

| Parameter | Value / Description |

|---|---|

| Product type | Bi-layer impact sound insulation roll |

| Roll width | 1050 mm |

| Roll length | 10 m |

| Thickness | 7 mm |

| Color | White |

| Material composition | Polymer layer with aluminized reflective fabric + polyester fiber mat (6 mm) |

| Surface mass | approx. 2200 g/m² |

| Impact sound insulation (ΔL) | 28–34 dB (depending on screed type, calculated per UNI EN ISO 12354) |

| Dynamic stiffness (s’) | 11 MN/m³ |

| Tensile strength (MD / CD) | 430 N / 5 cm (MD)300 N / 5 cm (CD) |

| Elongation (MD / CD) | 2–3% (MD)3–4% (CD) |

| Thermal conductivity (λ) | 0.0431 W/m·K |

| Thermal resistance (R) | 0.1647 m²K/W |

| Thermal transmittance (U) | 6.0716 W/m²K |

| Waterproof / vapor barrier | Yes |

| Radiant floor compatibility | Yes |

| Installation position | Under screed |

| Typical applications | Residential floors, radiant systems, lightweight screeds |

On-Site Acoustic Performance

Measured in residential building (Category A):

-

Brick–concrete slab + radiant floor

-

L’n,w = 49.0 dB (in situ value)

Evaluation according to UNI EN ISO 717-1.

Installation Guidelines

-

Install on a clean and level substrate

-

Overlap rolls using the integrated lateral selvedge

-

Apply AKUSTIK® BORDER polyethylene perimeter band to prevent acoustic bridges

-

Suitable for installation beneath:

-

Traditional screeds

-

Lightweight screeds

-

Self-leveling screeds

-

Summary

PHONOSTEP® is a reliable and high-performing solution for footfall noise insulation in modern floor systems.

Its combination of acoustic efficiency, mechanical resistance, moisture protection, and thermal contribution makes it ideal for residential projects requiring long-term performance and compatibility with radiant heating.

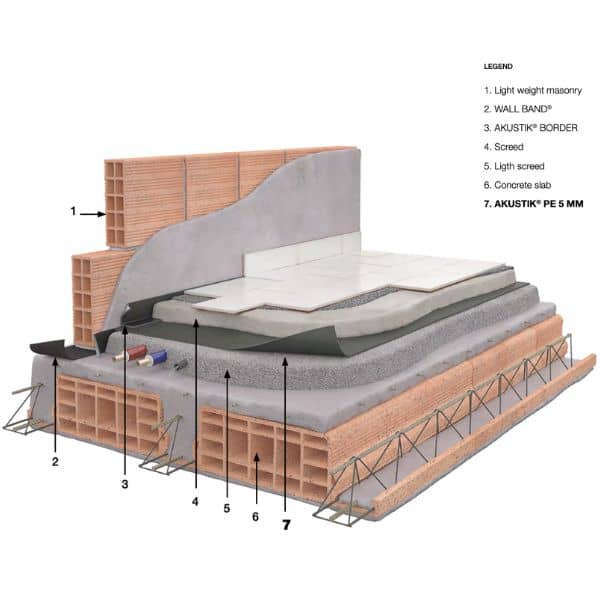

AKUSTIK®-PE – Cross-Linked Polyethylene Impact Sound Insulation

Soundproofing: Impact Noise

Category: Floor / Slab

Density: 33 kg/m3

ΔL: 26.5-28 db

AKUSTIK®-PE is a cross-linked expanded polyethylene insulation layer with a closed-cell structure, designed for impact sound and thermal insulation in horizontal building elements.

Its low density, high elasticity, and excellent compression resistance make it particularly suitable for floating floors and parquet systems.

The material offers stable long-term performance with minimal permanent deformation and can be supplied with additional surface treatments to enhance mechanical or thermal properties.

Key Features and Application

AKUSTIK-PE Key Features

Closed-Cell Structure – Prevents moisture absorption

High Compression Resistance – Maintains performance under load

Flexible & Easy to Cut – Adapts easily to site conditions

Thermal Insulation – Low thermal conductivity

Optional Surface Finishes – Protective embossed film or aluminum reflective layer

Self-Adhesive Option Available – Simplifies installation

AKUSTIK-PE Applications

Floating floors and parquet systems

Residential and commercial buildings

Impact noise insulation under screeds

Plant engineering, casings, and duct insulation

Thermal and acoustic insulation of technical installations

Technical Specifications – AKUSTIK PE

| Parameter | Value / Description |

|---|---|

| Product type | Impact sound and thermal insulation layer |

| Material | Chemically cross-linked expanded polyethylene |

| Cell structure | Closed-cell |

| Density | 33 kg/m³ |

| Available thicknesses | 3 mm, 5 mm, 10 mm (others on request) |

| Roll height | 1080 / 1500 mm (3 mm)1500 mm (5 & 10 mm) |

| Roll length | 150 m (3 mm)100 m (5 mm)50 m (10 mm) |

| Color | Charcoal grey |

| Dynamic stiffness (s’) | 34 MN/m³ (5 mm)28 MN/m³ (10 mm) |

| Resonance frequency | 64 Hz (5 mm)58 Hz (10 mm) |

| Thermal conductivity (λ) | 0.035 W/m·K |

| Thermal resistance | −80 °C to +100 °C |

| Reaction to fire | Class F (B-s1,d0 on request) |

| Optional finishes | Embossed black protective film or aluminum reflective coating |

| Installation position | Between subfloor and finished floor |

| Typical applications | Floating floors, parquet, screeds, technical insulation |

Acoustic Performance

-

Forecast impact sound level (in situ):

L’n,w = 54.8 dB

(calculated according to UNI EN 12354-2) -

Improvement of impact sound insulation:

-

5 mm: ΔLₙ,w = 26.5 dB

-

10 mm: ΔLₙ,w = 28.0 dB

-

Installation Guidelines

-

Install on a clean, flat substrate

-

Cut easily to size thanks to flexible material structure

-

Available with self-adhesive backing for easier positioning

-

Adhesive backing assists placement but is not a permanent bonding system

-

Use AKUSTIK® BORDER L-shaped polyethylene perimeter band to eliminate acoustic bridges

Summary

AKUSTIK®-PE is a versatile and efficient solution for impact noise control and thermal insulation in modern floor systems.

Its closed-cell structure, low dynamic stiffness, and installation flexibility make it ideal for projects requiring reliable acoustic performance and durability.

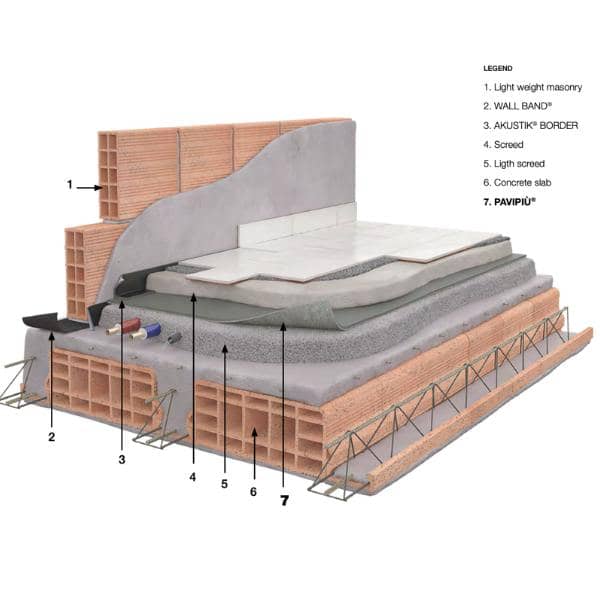

PAVIPIÙ® – High-Performance Bi-Layer Impact Sound Insulation Roll

Soundproofing: Impact Noise

Category: Floor / Slab

Density: 33 kg/m3

ΔL: 28-34 db

PAVIPIÙ® is a bi-layer impact sound insulation roll engineered for very high acoustic performance in horizontal floor constructions.

It combines a cross-linked polyethylene layer with a technical needle-punched fabric, achieving excellent impact noise reduction together with reliable thermal insulation.

Thanks to its low dynamic stiffness, PAVIPIÙ® is particularly effective in modern residential buildings and is fully compatible with radiant floor systems.

Key Features and Application

PAVIPIU Key Features

Bi-Layer Structure – Elastic polyethylene + acoustic technical fabric

Low Dynamic Stiffness – Optimized for footfall noise control

Durable & Stable – Maintains performance under load

Thermal Insulation Contribution – Low thermal conductivity

Designed for Double-Screed Systems – Ideal in complex floor build-ups

PAVIPIU Applications

Residential buildings and apartments

Traditional and modern floor constructions

Double-layer screed systems

Floors with radiant (underfloor heating) systems

It is typically installed above the lightweight filling screed and below the final bedding screed.

Technical Specifications – PAVIPIU

| Parameter | Value / Description |

|---|---|

| Product type | Bi-layer impact sound insulation roll |

| Roll width | 1500 mm |

| Roll length | 50 m |

| Total thickness | approx. 9 mm |

| Color | Anthracite grey |

| Material composition | Cross-linked polyethylene (5 mm, 33 kg/m³)Needle-punched technical fabric (4 mm, 300 g/m²) |

| Density (PE layer) | 33 kg/m³ |

| Dynamic stiffness (s’) | 11 MN/m³ |

| Resonance frequency | 37 Hz |

| Impact sound insulation improvement (ΔL) | 28–34 dB (depending on screed type, calculated per UNI EN ISO 12354) |

| Thermal conductivity (λ) | 0.036 W/m·K |

| Installation position | Between lightweight screed and final screed |

| Radiant floor compatibility | Yes |

| Typical applications | Residential floors, radiant systems, double screeds |

On-Site Acoustic Performance

Measured in residential buildings (Category A):

-

Brick slab + radiant floor system

-

L’n,w = 46.0 – 47.0 dB (in situ values)

Evaluation based on on-site measurements performed according to UNI EN ISO 140-7.

-

-

10 mm: ΔLₙ,w = 28.0 dB

-

Installation Guidelines

-

Install with the technical fabric facing downward

-

Seal joints using AKUSTIK® BAND

-

Apply AKUSTIK® BORDER L-shaped polyethylene perimeter band to avoid acoustic bridges

-

For screeds thinner than 50 mm, reinforcement of the screed is recommended

-

Supplied in roll form for fast and easy installation

Summary

PAVIPIÙ® is a premium solution for impact sound insulation in floor systems where very low dynamic stiffness and high acoustic efficiency are required.

Its bi-layer composition ensures excellent footfall noise control while remaining compatible with radiant heating and modern construction practices.

SOUNDPROOFING MEMBRANES

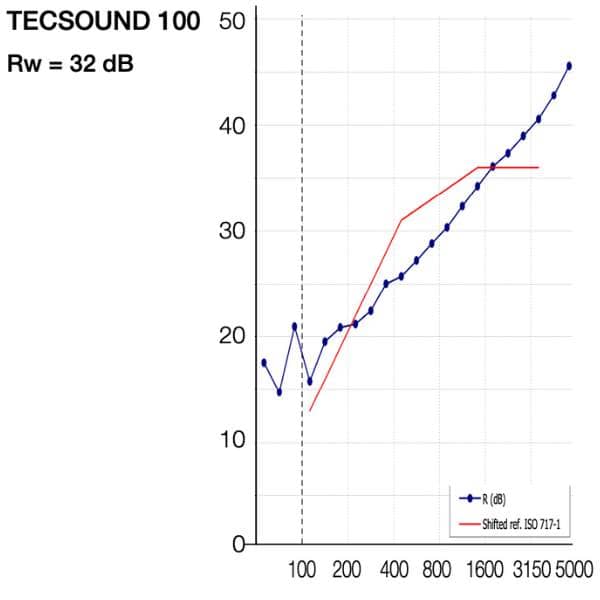

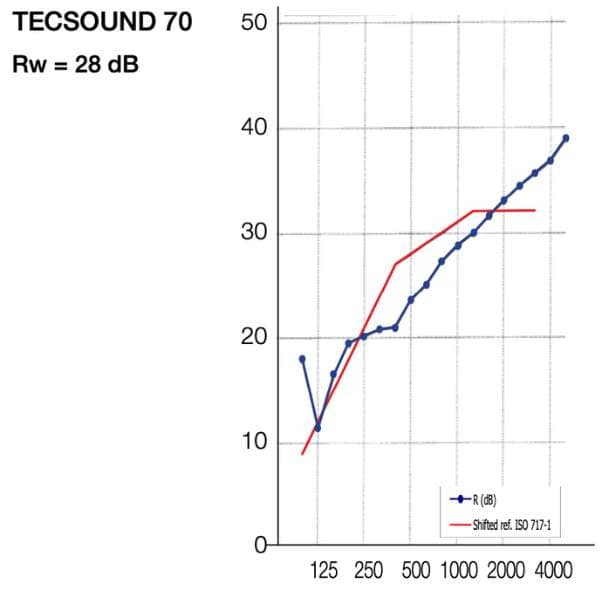

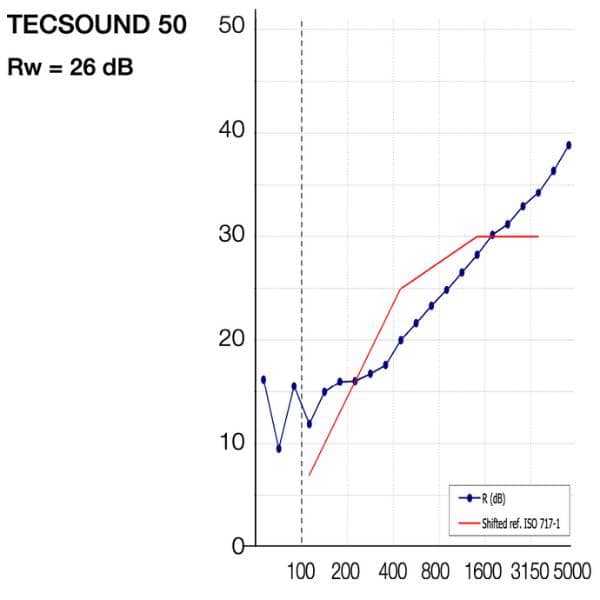

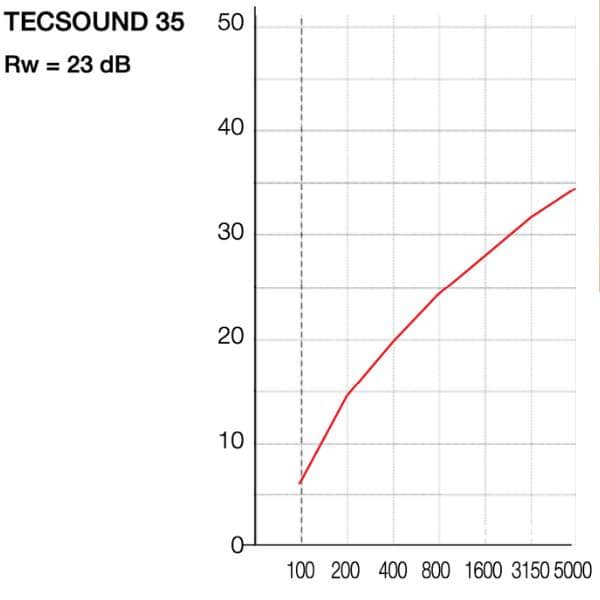

TECSOUND – High-Density Acoustic Membrane for Airborne and Structural Noise Insulation

Soundproofing: Impact Noise, Airborne Noise

Category: Universal, Flexible

Density: 4 – 10 kg / m2

Rw: 23 – 32 db

TECSOUND is a high-density, viscoelastic synthetic membrane designed to deliver superior soundproofing performance across a wide range of construction and industrial applications.

Thanks to its flexibility and adaptability, it can easily conform to any surface or shape, providing exceptional airborne and structural noise reduction.

Available in multiple densities and thicknesses, TECSOUND membranes combine acoustic efficiency, fire resistance, and long-term durability in one versatile solution.

Key Features and Application

Key Features

Flexible & Easy to Install – Easily adapts to irregular shapes and curved surfaces.

Durable & Rot-Proof – Resistant to moisture, aging, and mechanical wear.

High Fire Resistance – Classified up to B-s1,d0 / B-s2,d0 for safety compliance.

High Density & Elasticity – Provides excellent damping for vibrations and resonance control.

Adhesive Option Available – For faster and simpler installation.

Applications

Typical applications include:

Walls and Ceilings: Plasterboard and gypsum systems for residential and commercial spaces.

Floors: Floating and wooden floors to minimize footfall noise and structural vibrations.

Roofs: Metal and wooden roofs to reduce rain and wind noise.

Industrial Uses: Soundproofing of doors, machinery housings, compressors, ducts, bins, and metallic enclosures.

Performance & Technical Data

| Model | Dimensions (mm) | Thickness (mm) | Weight (kg/m²) | Sound Reduction (Rw) | Fire Classification |

|---|---|---|---|---|---|

| TECSOUND 35 | 1000 × 10000 | 2.0 | 4 | 23 dB | B-s1,d0 |

| TECSOUND 50 | 1220 × 6000 | 2.5 | 5 | 26 dB | B-s2,d0 |

| TECSOUND 70 | 1220 × 5000 | 3.5 | 7 | 28 dB | B-s2,d0 |

| TECSOUND 100 | 1220 × 4000 | 5.0 | 10 | 32 dB | B-s2,d0 |

Installation

-

Can be installed directly on surfaces or layered between building materials.

-

Supplied in roll form; available with self-adhesive backing for simplified application.

-

Compatible with plasterboard, metal, wood, and concrete substrates.

-

Ideal for integration into horizontal (floor) and vertical (wall, ceiling) sound insulation systems.

Performance Highlights

-

Certified laboratory sound reduction index according to ISO 10140-2 standards.

-

Demonstrated high damping performance in airborne noise and vibration isolation.

-

Proven reliability in both residential and industrial acoustic systems.

Summary

TECSOUND delivers professional-grade soundproofing for projects demanding superior acoustic comfort and compliance with modern construction standards.

Its high mass, flexibility, and ease of installation make it one of the most effective membranes for improving sound insulation in walls, floors, ceilings, and industrial enclosures.